DUST COLLECTION SYSTEMS

Provide a cleaner and safer work environment alongside increased manufacturing efficiencies

Controlling dust is a key step in improving air quality

In nearly every industrial facility, a dust collection system is a vital component for efficient operation. Their operation, reliability and efficiency directly impact profits at your facility.

- Cartridge

- Baghouse

- Filter Booth

- Downdraft Tables

- Wet Collectors

- Cyclones

- Portable Units

Dynacom's product offering includes many familiar brands

Dynacom has been recognized for consistently high performance by both customers and suppliers.

Industrial Dust Collection Systems

Manufactured by A.C.T. Dust Collectors

Industrial dust collection systems from A.C.T. Dust Collectors are quality-built in the United States to stand up to your rugged manufacturing environment. From small to large jobs, our industrial dust filtration systems are designed to handle many applications, including welding smoke, grinding, cutting tables, blast applications, sanding, thermal spray, coating, bulk powders, and many more dust-producing processes. No matter your business application, we have an industrial dust mitigation system. Our technicians and quality control teams ensure every industrial dust collection system is up to our standards before stamping our serial number on it.

From our tried-and-proven cartridge dust collectors to our LaserPack, we offer a wide selection of high-value dust collectors that fit most industrial needs. We can handle nearly any process that generates dust, providing outstanding customer service and excellent value to all our customers.

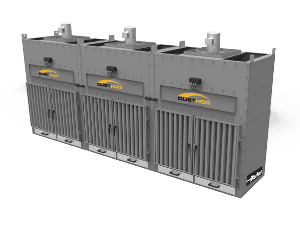

DustHog Cartridge Collectors

Manufactured by Parker

Reverse pulse cleaning cartridge style dust collectors are the most commonly applied technology for fine dust and dry smoke applications. Available in a variety of configurations we have the system to meet your requirements.

Download DustHog Cartridge Brochure >

Download DustHog SFC Brochure >

Enclosureless Baghouses

Manufactured by Nederman

Enclosureless baghouses are ideal for woodworking and other large particle dust collection systems and acceptable for use in some combustible dust applications.

Wet Dust Collectors

Manufactured by Diversitech

When your work application produces dangerous byproducts, it’s necessary to find safe and efficient solutions that remove these risks from the equation and allow work to carry on unabated. One particularly dangerous byproduct is combustible dust. Combustible dust refers to metallic or non-metallic airborne dust capable of causing an explosion in your workspace. The determining factor on whether or not industrial dust is combustible lies in its KST value, which measures how explosive dust is when compared to other types of dust. Any reading higher than zero indicates the risk of explosion. Work applications that can produce combustible dust create some of the most hazardous work conditions imaginable if the dust is not contained and removed safely.

Consequences of a serious combustible dust incident include:

- Serious injury or death to nearby workers

- Severe property damage

- Irreversible environmental damage

- Long-term business interruption

Wet dust collectors & wet downdraft tables by Diversitech can help you neutralize combustible dust issues. Contact us for help.

Uni-Wash Wet Collectors

Manufactured by Provent

Built for heavy industrial use, Uni-Wash Wet dust collectors are required for the safe collection of combustible metal dust such as aluminum dust collection, titanium dust collection and magnesium dust collection. ProVent’s line of Uni-Wash Wet Dust Collectors have also been used effectively in many other difficult applications in lieu of cartridge collectors in industries such as food processing dust collection and pharmaceutical dust collection.

Boss Products Explosion Mitigation Products

Manufactured by Boss Products

We provide a full range of fire and explosion mitigation solutions - including prevention, isolation, diversion, and venting - which address potential hazards in the industrial filtration and process industries.

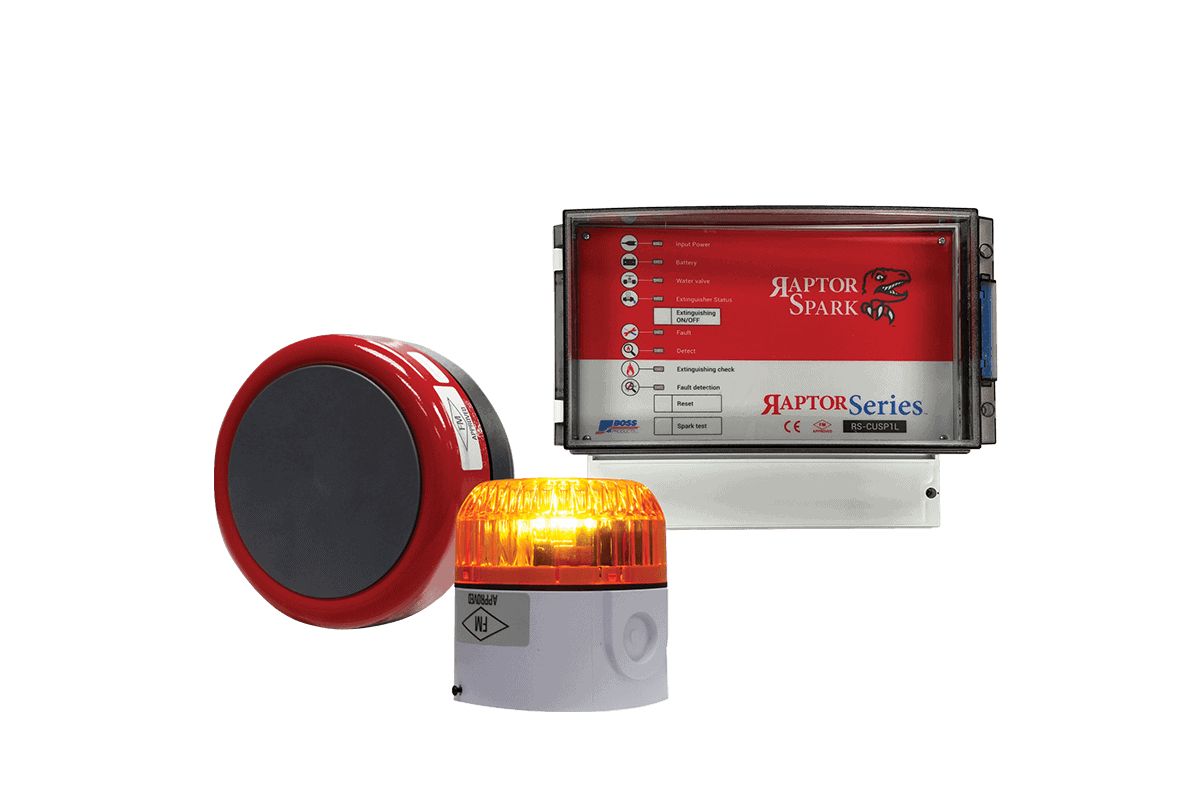

Raptor Spark Detection and Extinguishing System

Manufactured by Boss Products

The Raptor Spark™ Detection and Extinguishing System is an FM-APPROVED safety device designed to detect and extinguish sparks and glowing embers traveling through a duct system. The Raptor Spark™ Detection and Extinguishing System is an essential Fire Protection, Fire Isolation, and Diversion device commonly installed with EcoMAXX® High Speed Abort Gates, FireBreak Shutters, EcoMAXX®/VigilEX Explosion Vents, and explosion-certified EcoMAXX®/VDL Rotary Valves. Typical automatic functions include hazard detection, system shut-down, isolation/abort, and extinguishment and/or suppression.

DustHog MCB Filter Booths

Manufactured by Parker

The MCB unit creates cross-draft ventilation that eliminates hazardous contaminants before recirculating clean air.

DustHog MIB Baghouses

Manufactured by Parker

The DustHog Modular Industrial Baghouse (MIB) provides a safe, effective, service friendly solution to handle the most challenging process and nuisance dust collection applications.

Portables

Manufactured by Diversitech

Ensure safe breathing zones for your workers with the FRED Jr. Portable Fume Extractor.

Removing weld fumes, dust and other airborne contaminants right as they are produced, the FRED Jr. is designed for easy transport and positioning. Equipped with a Merv 15 rated Nanofiber filter that captures airborne contaminants as small as 0.5 micron, cleaner air is guaranteed.

Downdraft Tables

Manufactured by Diversitech

Any fumes, smoke or dust from your production activities can

be captured right as they are produced, before compromising your

indoor air quality.

Source Extraction Arms

Manufactured by Diversitech

Wall mount fume extraction arms allow the operation to position the hood directly over the source to improve capture of the smoke and dust. These arms can be used in conjuction with other filtration devices or to exhaust the air outside.

Applications for Dust Collection

- Abrasive Blasting

- Batch Mixing

- Food Processing

- Foundries

- Grinding

- Laser and Plasma Cutting Tables

- Powder Coating

- Sanding

- Welding

- Woodworking

Growing manufacturer eliminates problem of weld smoke in new building

When moving the weld department into their new state of the art facility in Streetsboro, Ohio, They wanted to make sure that they maintained the cleanest, healthiest environment for their employees.

Related Product Materials

Contact us for assistance

If you have a question, need information or would just like to chat with us, feel free to drop us a line.

If you're in need of technical product assistance on existing equipment, please contact us by phone as you will get a response more quickly: (440) 543-1900. Thank you.

"*" indicates required fields