Author: Tony Pfenning

In the world of industrial facilities, a well-designed dust collection system is essential for maintaining a clean and safe environment. Not only does it protect the health of employees, but it also ensures compliance with air quality regulations. So, how can you create an effective dust collection system that meets the unique needs of your facility? By understanding the intricacies of dust types and properties, workspace layout, equipment design, and safety measures, you can develop a customized solution that optimizes dust removal while maintaining cost efficiency.

In this blog post, we will guide you through the essential considerations for designing an effective dust collection system. You’ll gain a clear understanding of dust types and properties, learn how to assess your workspace layout and airflow needs, explore various dust collector designs, and much more. By the end of this post, you’ll be well-equipped to create a dust collection system that addresses your facility’s specific challenges and requirements.

Understanding Dust Types and Properties

In order to design an effective dust collection system, it’s paramount to comprehend the types and properties of dust produced in your facility. Dust properties can vary depending on the material being processed and the equipment in use, and these factors will influence your choice of dust collector design and filter media. For example, some dust types (such as smoke produced from welding) may require a higher level of filtration than others (such as metal debris generated in a metalworking shop).

Furthermore, dust properties can have a significant impact on the overall system design, from the layout of ducts and hoses to the selection of the appropriate fan or blower. The National Fire Protection Association (NFPA) sets guidelines for handling various types of dust, making it essential to determine how much dust your facility produces and what kind of dust collection system would be most suitable.

Taking into account the unique characteristics of dust generated in your facility will aid in tailoring a dust collection system that not only meets regulatory requirements but is also optimized for efficient dust removal.

Assessing Workspace Layout and Airflow Needs

The layout of your workspace and the airflow requirements also play a crucial role in determining the efficiency of your dust collection system. Properly assessing these aspects will help you optimize the placement of dust collectors, ductwork, and connections, ensuring that dust is captured as close to the source as possible.

When designing the layout of duct runs, it’s essential to consider factors such as short duct runs, minimal turns, and the least amount of flex hose required to connect tools to the ductwork. Additionally, it’s important to balance the system’s static pressure and airflow requirements to ensure adequate air velocity for conveying fumes and dust through the ducts.

A diligent evaluation of your workspace layout and airflow needs will allow you to establish a dust collection system that excels in both efficiency and effectiveness in dust removal, including the proper use of each tool’s dust port.

Choosing the Right Dust Collector Design

Selecting the right dust collector design is essential for an effective dust collection system. There are several types of dust collectors available, each with its own advantages and applications. Some of the most common designs include baghouse collectors, cartridge collectors, and cyclone collectors.

When choosing a dust collector design, it’s crucial to consider the type of material being processed and the properties of the dust. Baghouses are ideal for collecting larger, sticky or higher temperature dust particles. Cartridge collectors are better suited for collecting smaller dust particles. Choosing a dust collector design that best suits your needs will guarantee efficient dust collection and removal in your facility.

Baghouse Collectors

Baghouse collectors are a popular choice for dust collection systems, utilizing fabric filter bags to effectively capture and remove dust particles from the air. These collectors are particularly suitable for managing adhesive or high-temperature dust and can accommodate large quantities of dust.

While baghouse collectors offer numerous advantages, such as:

- efficient dust collection

- cost-efficiency

- adaptability

- environmental compliance

- straightforward maintenance

They do come with some drawbacks. The primary disadvantage is the necessity for frequent filter bag replacement. However, considering their effectiveness in handling challenging dust types, baghouse collectors remain a popular choice for many industrial applications.

Cartridge Collectors

Cartridge collectors are another popular dust collection system design, utilizing cylindrical cartridges to capture dust particles. These collectors are an optimal choice for capturing fine dust particles due to their construction, which is composed of a material that captures particles as small as 0.5 microns. Choosing the right dust collection system, such as cartridge collectors, can greatly improve the efficiency of your collection system.

One of the main benefits of cartridge collectors is their ease of maintenance and replacement. The cartridges can be removed, cleaned, or replaced as necessary, making them a user-friendly option for facilities that require efficient dust collection with minimal downtime.

Cyclone Collectors

Cyclone collectors use centrifugal force to separate dust particles from the air, making them particularly effective for capturing larger dust particles. These collectors offer advantages such as:

- Cost-effectiveness

- High collection efficiency

- Easy maintenance

- Space-saving design

- Improved overall efficiency

While cyclone collectors are effective for larger dust particles, they may not be the best choice for capturing fine dust. Facilities dealing with fine dust may want to consider other collector designs, such as cartridge collectors, to ensure optimal dust collection. Regardless of the dust type, understanding the specific needs of your facility is essential for selecting the most appropriate dust collector design.

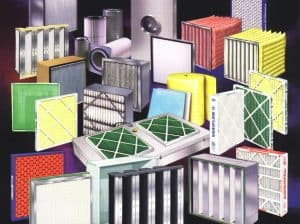

Selecting Appropriate Filter Media

Choosing suitable filter media is a pivotal step towards efficient dust collection. The right filter media will depend on the type and properties of the dust generated in your facility. Some common filter media options include fiberglass, nylon, and polyester filters, each with different capabilities and applications.

When selecting filter media, it’s essential to consider factors such as air quality, along with:

- The air-to-cloth ratio, which determines the longevity of a filter

- The unique characteristics of the dust produced in your facility

- The specific requirements of your dust collection system

Taking these factors into account will guide you towards the most effective filter media, ensuring optimal dust removal and system efficiency.

Implementing Safety Measures and Explosion Protection

Safety is paramount when designing and operating a dust collection system, especially in facilities dealing with combustible dust. To protect personnel and equipment, it’s essential to implement safety measures and explosion protection methods, such as spark detection systems, sprinkler vents, and reinforced dust collector designs.

Adherence to local and national regulations, ensuring the dust collector is rated for proper pressure, and protecting ductwork from explosion hazards will minimize the risk of accidents and ensure the safe operation of your dust collection system. Remember, a well-designed and safely operated dust collection system not only protects your employees but also helps maintain compliance with industry standards and regulations.

Balancing Hoods, Ducts, and Connections

Properly balancing hoods, ducts, and connections in your dust collection system is essential for efficient airflow and dust collection. Blast gates, mechanical components that manage vacuum pressure distribution, play a crucial role in maintaining system balance by regulating air flows across different sections of the facility.

Secure connections between ducts and hoods are also vital for preventing leaks and maintaining system balance. Ensuring all connections are properly sealed and that blast gates are functioning correctly will optimize airflow and boost the overall efficiency of your dust collection system.

Remember, an efficient and well-balanced system not only provides better dust collection but also helps reduce energy consumption and operational costs.

Fan Selection and Sizing

Choosing the right fan or blower for your dust collection system is another important factor that impacts system efficiency and dust removal. The appropriate fan ensures optimal airflow, conveying fumes and dust through the ducts effectively.

When selecting and sizing fans for your dust collection system, it’s important to determine whether the fan should be located on the side of the clean air or the dirty air and to consider factors such as the required airflow rate and pressure. A careful consideration of these aspects will guide you to the right fan or blower selection, ensuring efficient dust collection and a clean, safe environment in your facility.

Regular Maintenance and Troubleshooting

Regular maintenance and troubleshooting are essential for maintaining the efficiency and effectiveness of your dust collection system. Performing routine inspections, cleaning filter media, and replacing worn or damaged components will prevent malfunctions and ensure your system operates at peak performance.

Ignoring proper maintenance guidelines can lead to:

- Inadequate performance

- Clogged ducts

- Breaches

- System imbalance

These issues can compromise the safety and cleanliness of your facility. Implementing a proactive maintenance program and addressing potential issues before they escalate will protect your investment and ensure compliance with industry regulations.

Customizing Dust Collection Systems for Specific Industries

Creating a dust collection system tailored to the specific needs of your industry is essential for optimal performance and compliance with regulations. For example, the pharmaceutical and food processing industries may have unique dust-related challenges and requirements that necessitate customized dust collection solutions.

When customizing a dust collection system for your industry, it’s important to consider the following factors:

- Dust collection hood design

- Unit placement

- Ducting placement and size

- Tailored system design for unique applications

Taking into account industry-specific challenges and requirements will help you create a dust collection system that is both efficient and compliant with relevant regulations.

Summary

Designing an effective dust collection system is a nuanced process, necessitating a comprehensive grasp of various factors—from dust types and properties to workspace layout, equipment design, safety protocols, and industry-specific mandates. In this regard, Dynacom has consistently showcased its expertise in facilitating informed decision-making, enabling businesses to devise tailored solutions that accentuate dust removal, endorse a pristine and secure environment, and adhere to industry standards.

As you venture to establish the quintessential dust collection system for your facility, leaning on the proven experience and insights from leaders like Dynacom can be invaluable. Their emphasis on precision and dedication to understanding distinctive needs has set a benchmark in the industry. Harnessing this knowledge ensures not only the well-being of your workforce but also unwavering regulatory compliance and the enduring prosperity of your enterprise.

Key blog takeaways

- Understanding dust types and properties is essential for designing an effective dust collection system.

- Assessing workspace layout and airflow needs, selecting the right collector design, filter media, and implementing safety measures & explosion protection are all key considerations when creating a customized system.

- Regular maintenance & troubleshooting must be performed to ensure optimal performance while meeting industry regulations.

Subscribe to blog updates

"*" indicates required fields

Contact us for assistance

If you have a question, need information or would just like to chat with us, feel free to drop us a line.

If you're in need of technical product assistance on existing equipment, please contact us by phone as you will get a response more quickly: (440) 543-1900. Thank you.

"*" indicates required fields